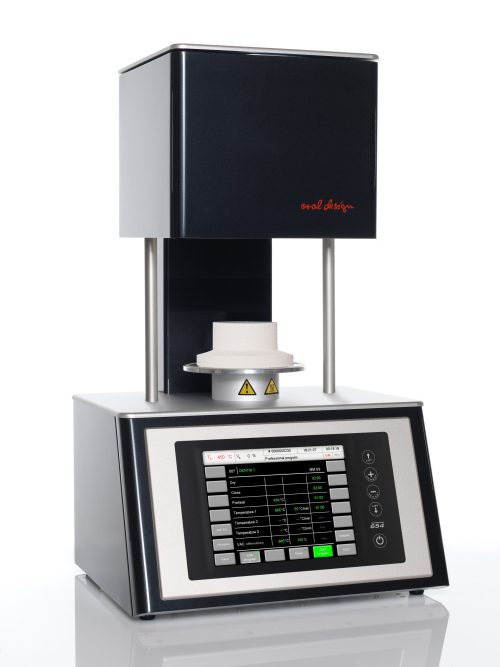

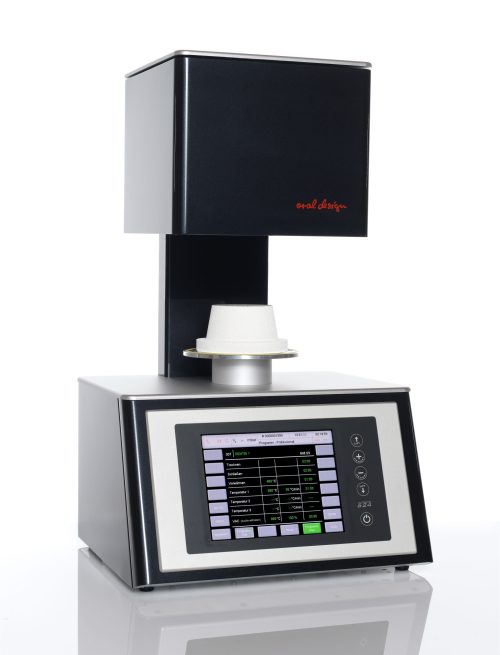

AUSTROMAT 674 Sintering Oven

£11,275.91 ex. VAT

High-Temperature Furnace up to 1560°C Sinter, Glaze & Crystallize under Atmosphere Chairside Speed Mode, Space for all common bridge sizes or up to 40 units in one level (Ø 100mm) with the option of a double stacker platform for up to 80 units over 2 levels.

Price includes delivery.

Limit of 1 item per order, for bulk purchases of this item, please contact [email protected]

Finance is available upon request with a 3rd party company.

Description

High-Temperature Furnace up to 1560°C Sinter, Glaze & Crystallize under Atmosphere Chairside Speed Mode, Space for all common bridge sizes or up to 40 units in one level (Ø 100mm) with the option of a double stacker platform for up to 80 units over 2 levels. AUSTROMAT 674 The SiC-heating concept for every kind of milled dental prosthesis sintered under atmosphere for as many as approximately forty parts per level. Three heating elements realize a homogeneous temperature distribution up to as high as 1.530 °C. Remote control and quality management are optionally integrated and provide a reliable partner of your milling or grinding machine.

FURNACE FOR SINTERING COPINGS UP TO 100 MM IN DIAMETER The AUSTROMAT 674 is equipped with three silicon carbide heating elements, perfectly fitting for sintering at temperatures up to 1.530 °C. These heating elements feature robustness and durability and will not discolour copings. The firing chamber is closed through the vibration free lift system. The AUSTROMAT 674 also uses our unique, well-established system, to realize safely shortest sintering durations with highest heating and cooling rates. This so-called Auto Dry system controls temperature gradients through lift movement, dependent on chamber temperature. On each sintering level approximately forty sintering units can be placed. Equip the furnace with two levels to reach highest throughput. Diameters of sintering goods may reach up to 100mm. Sintering programs are already factory pre-set, loaded through a thumb drive or optionally downloaded from the huge DEKEMA sintering program internet data base. Optionally these cycles might even be programmed by one click QR scanning. The furnace is operated through its large 7.5″ touch panel. It also shows the state of the furnace and all relevant data.